S-Oil makes $7b Shaheen petrochemical project official

Massive project marks largest-ever investment made in Korea by Aramco

By Hong YooPublished : Nov. 17, 2022 - 15:44

South Korean oil refiner S-Oil, owned by Saudi Arabia’s Aramco, on Thursday confirmed its $7 billion massive project of building a large-scale petrochemical plant in the nation’s southeastern city of Ulsan.

The so-called “Shaheen Project” is the largest investment made in Korea by Aramco that holds 63.4 percent shares in the refiner.

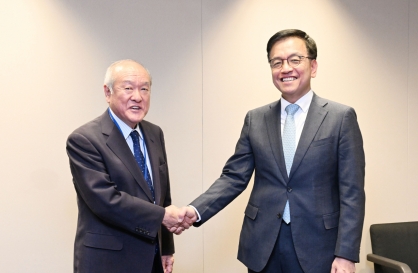

The announcement comes as Saudi Arabian Crown prince Mohammed bin Salman was visiting Seoul to hold talks with President Yoon Suk-yeol and business leaders, including Samsung Electronics Chairman Lee Jae-yong, to develop economic ties between the two countries.

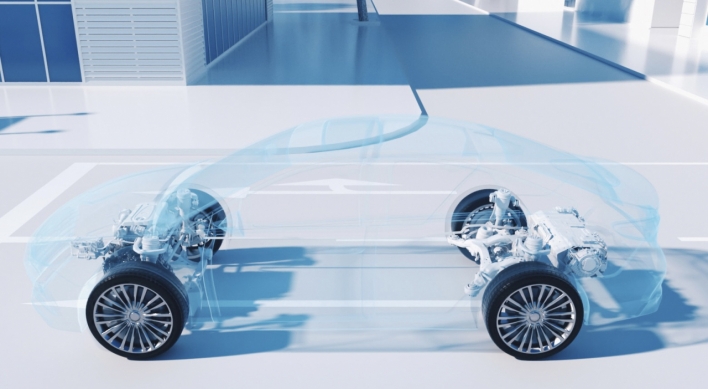

The project involves establishing the world’s largest refinery-integrated petrochemical steam crackers to produce up to 3.2 million tons of petrochemicals annually.

Utilizing Aramco’s cutting-edge thermal crude-to-chemicals (TC2C) technology on the steam cracker will allow the oil refiner to produce high-quality petrochemicals as feedstock for plastics and other synthetic materials, according to the company.

The TC2C process involves using low-quality heavy oil which is processed in the existing refinery to make feedstock for steam crackers such as naphtha and off-gas.

This is the first time Aramco’s TC2C technology has been commercialized, with the hope of giving the new project a competitive edge when compared to older-generation crackers.

The steam cracker, then, treats these by-products from crude processing to produce ethylene, propylene, butadiene, and benzene.

The plant will also produce polyethylene used as feedstock for making plastics and other synthetic materials.

The project also supports S-Oil’s ambition to operate more efficiently by recovering and recycling waste heat from the steam cracker and improving overall energy efficiency.

The project is expected to create jobs for 17,000 workers per day during construction stage and generate 3 trillion won ($2.2 billion) in value to the Ulsan local construction industry, says the refiner.

"We have taken the first step on a great journey of development. With the full support of the governments of our two countries, our successful track record in delivering major projects and the outstanding professionalism of our team, we are confident that Shaheen will not only diversify our portfolio towards chemicals but also deliver industry-leading energy efficiency,” said S-Oil CEO Hussain Al-Qahtani.

The project will begin next year with completion targeted for 2026.

Once completed, S-Oil’s chemical yield based on volume will more than double to 25 percent by 2030 from the current 12 percent.

The Shaheen project follows S-Oil’s first-phase investment of $4 billion in a petrochemical expansion project completed in 2018.

-

Articles by Hong Yoo

![[Kim Seong-kon] Democracy and the future of South Korea](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/16/20240416050802_0.jpg&u=)

![[Today’s K-pop] Zico drops snippet of collaboration with Jennie](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/18/20240418050702_0.jpg&u=)