Samsung BioLogics seeks partners for Alzheimer’s pipelines

Top Korean CDMO adds biosafety testing service to its portfolio for end-to-end client solutions

By Lim Jeong-yeoPublished : Nov. 6, 2019 - 16:16

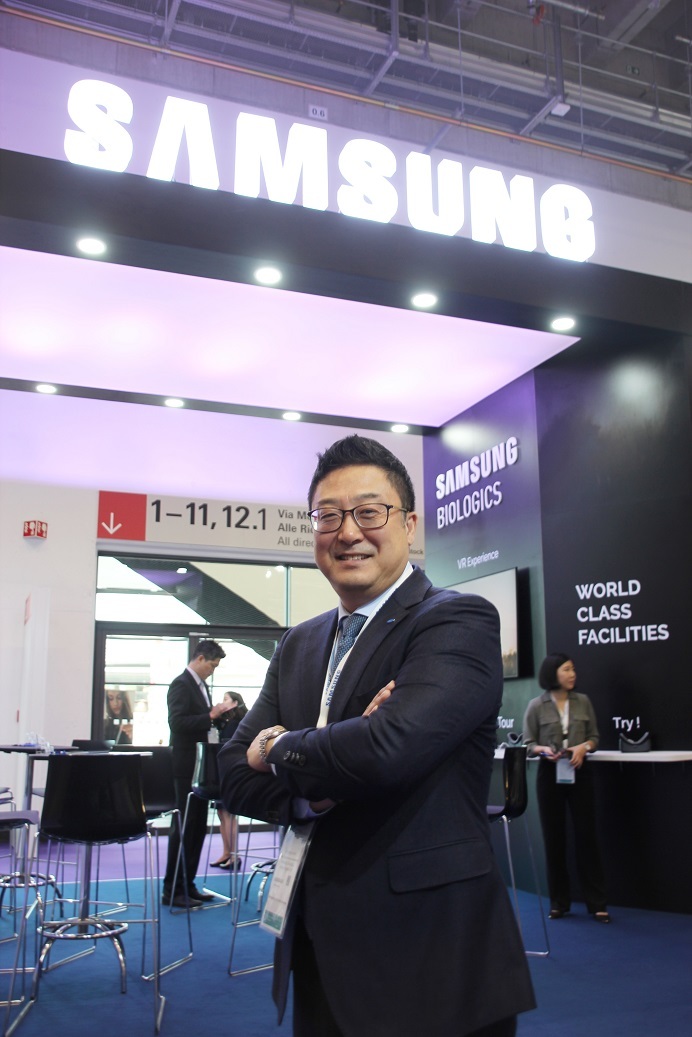

FRANKFURT, Germany -- South Korea’s Samsung BioLogics is upbeat with the addition of a biosafety testing service to its portfolio and is seeking partnerships with companies developing therapies for Alzheimer’s disease.

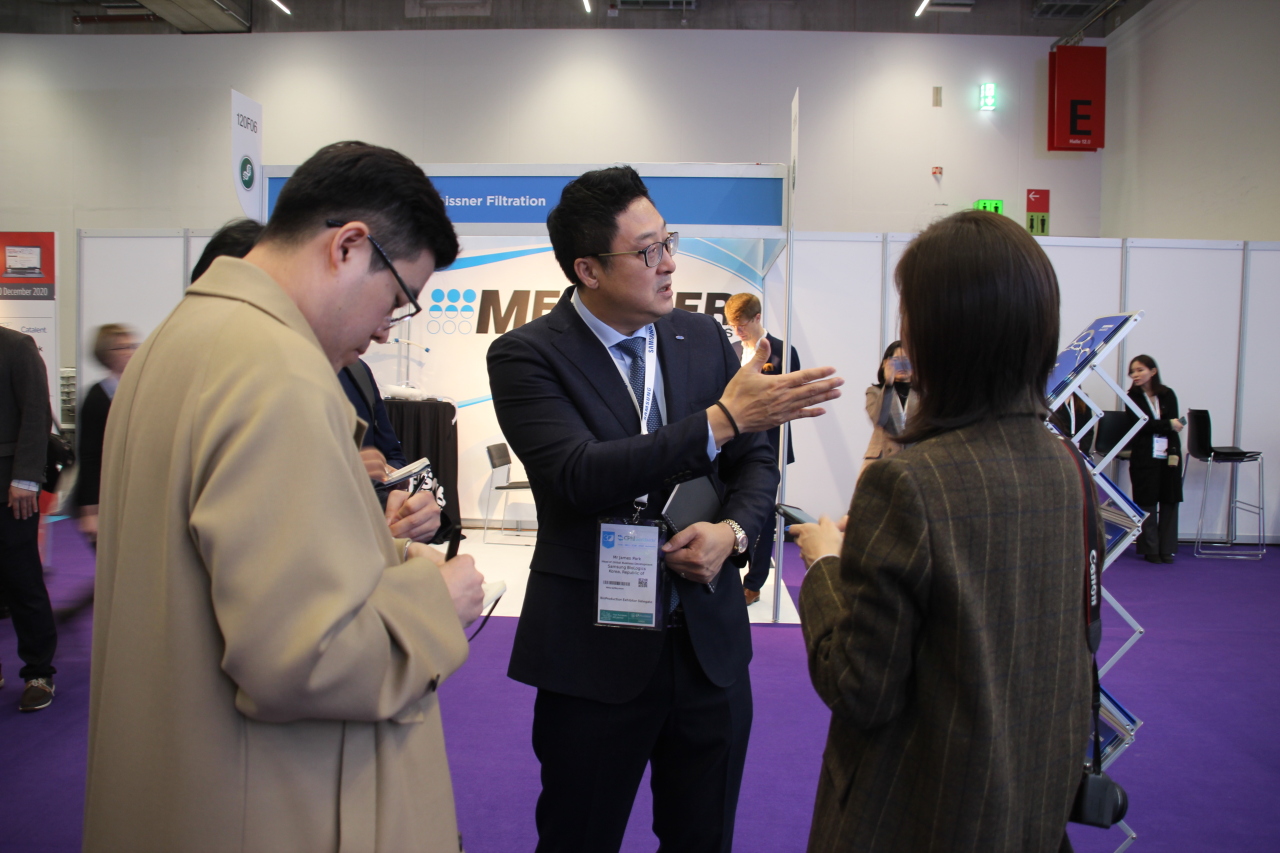

“We have already contacted over 20 companies that may reignite their Alzheimer’s drug pipeline after Biogen’s possible aducanumab approval in the US on Dec. 5,” Samsung BioLogics Senior Vice President and global head of Business Development James Park told reporters at the 30th CPhI Worldwide 2019 in Frankfurt, Germany.

“We have already contacted over 20 companies that may reignite their Alzheimer’s drug pipeline after Biogen’s possible aducanumab approval in the US on Dec. 5,” Samsung BioLogics Senior Vice President and global head of Business Development James Park told reporters at the 30th CPhI Worldwide 2019 in Frankfurt, Germany.

The market for Alzheimer’s has untapped potential, large enough to accommodate all other major contract development and manufacturing organizations, including Lonza, Boeringher Ingelheim and WuXi.

The US Food and Drug Administration’s decision on Biogen’s experimental Alzheimer’s treatment in December will be a jolt to companies with similar projects, and they may actively seek a CDMO partner, said Park.

“We have already contacted relevant companies in case they require our service,” Park said, “The huge amount of contracts will serve as a catalyst for the construction of our fourth plant.”

Samsung BioLogics has a large vacant plot next to its existing three plants in Songdo, Gyeonggi Province, where it hopes to build its next facility. The company currently has a capacity of 362,000 liters of biopharmaceuticals in a single generation -- a huge amount that surpasses industry standards. It was this capacity, tied with its experience working with international big pharma firms Roche and BMS in its initial years, which helped the company bag 42 drug approvals in four years despite being a latecomer in the field.

Samsung BioLogics’ business competitiveness comes from reliability, scalability and flexibility, Park said. It always makes on-time delivery of products, matches any volume of manufacturing and accommodates the various needs of clients.

From 2011 when it first started out as a CMO to its expansion to contract development in 2017, Samsung has constantly added new services to its portfolio for full end-to-end solutions.

Now the company not only does research to identify drug candidates for clients and assist them in applying for regulatory approvals for novel drugs, but also provides post-manufacturing biosafety testing services.

“We have achieved our goal for 2019 through the addition of BTS to our service,” said Park, “There is no missing link in the services we can provide.”

Samsung BioLogics can now manage its parallel projects in a faster manner through independent handling of the biosafety tests.

“With our experience and technology, we can drastically shorten the tasks that now take six-eight months to four months,” said Park.

Starting this year, Samsung BioLogics is focusing on a new business unit that does small-scale CMO and drug product, the formulation or packaging of drug substance, he said.

“With our capacity to handle 2x1,000 liters’ volume, we will not only manufacture biologics drug, but also cover small molecules and vaccines. We also have to build the capacity to handle prefilled syringes.”

At the CPhI Worldwide 2019, a number of Samsung BioLogics representatives gave presentations at various sessions.

Richard Lee, head of drug product business unit, and Executive Director of Drug Product Account Management Brad Larson spoke on the increasing use of single-use bioreactors over multiuse stainless steel bioreactors for small-scale developments.

Samsung BioLogics head of Cell Culture Manufacturing Ken Green introduced the company’s manufacturing facilities -- its third plant, with 12 bioreactors each producing 15,000 liters of biopharmaceuticals, adopted N-1 perfusion technology in August under his supervision, increasing the throughput sevenfold through faster cell growth.

By Lim Jeong-yeo (kaylalim@heraldcorp.com)

Korea Herald correspondent

![[KH Explains] Hyundai's full hybrid edge to pay off amid slow transition to pure EVs](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/18/20240418050645_0.jpg&u=20240419100350)

![[Today’s K-pop] Zico drops snippet of collaboration with Jennie](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/18/20240418050702_0.jpg&u=)